Reliable & Rugged Ultrasonic Sensors for Every Industry

Precision. Durability. Performance.

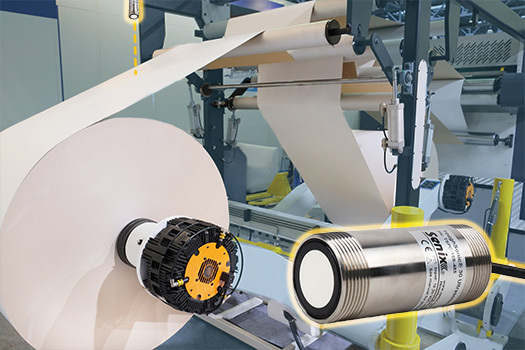

Senix ToughSonic® general purpose and chemical-resistant sensors are an affordable, reliable choice for automation and level and distance measurement in industrial, agricultural, and marine applications.

ToughSonic-100 and -200 series sensors provide high-accuracy liquid level monitoring in tanks, industrial containers, and in open-air environments.

Senix sensors are a durable choice for flood and river level monitoring. Or utilize ultrasonic sensors for responsive tank level measurements in processing and sanitary environments.

Heavy equipment and maritime operations rely on our durable transmitters for distance ranging and obstacle avoidance in nautical, bridge, or road construction sites.

Senix has been a force in ultrasonic level and distance sensors for over 35 years. No matter what your application—municipal wastewater, civil engineering, fertilizer tanks, and everything in between—there's a ToughSonic for every industry.

Versatile. Customizable. Tough. Smart. Connected.

Featured Products

Why Choose Senix?

Durable & Weatherproof

IP68-rated for extreme conditions

High-Precision Sensing

Reliable measurements in tough environments

Easy Integration

Multiple outputs, remote monitoring and IOT-ready

Custom Solutions

Tailored sensors for unique applications

Senix Serves Your Industry.

Tank Level Monitoring

Monitor your tanks,

vats, & other large

liquid vessels

Agriculture

Precision farming

including irrigation,

sprayers & crop heights

Marine

Ship & barge distancing,

hydrofoil boats,

& wave profiling

Environmental

River levels, stormwater,

droughts, floods,

& tsunamis

Civil Engineering

Road and bridge

construction &

structural monitoring

More About Senix

Senix became a part of Garner Industries, LLC—headquartered in Lincoln, Nebraska, USA—in 2024.

Senix is a sister company to BinMaster level sensors and inventory software serving the agriculture and process industries since the early 1960s.

Featured Applications

Water Monitoring

In Tanks, Rivers, & Streams

Tank Level Monitoring

For Benign Liquid & Chemical Levels

Civil Engineering

Safer & Smoother Construction & Repairs

Distance Ranging

For Industrial & Automotive Automation