ToughSonics® Accurately Measure Diesel for Rail Applications

From regional short line freight service to coast-to-coast passenger trains, railroads depend on diesel power. With increasing investments in new technology, diesel engines, and repowering and replacement of existing engines, railroads are poised for achieving greater service and efficiency goals. Senix's non-contact ultrasonic sensors help achieve peak efficiency with accurate and proactive diesel fuel measurements.

Diesel power is proven technology and provides efficiency, durability, reliability, and now near-zero emissions. It has long been the technology of choice for moving people and goods by rail.

The Power of Diesel, By the Numbers

In 2018—according to data from the U.S. Bureau of Transportation Statistics (BTS)—just over 26,000 freight and 431 passenger rail locomotives were in operation in the United States. Except for a few passenger rail lines that are electrified, the remainder of passenger rail and all of freight rail in the U.S. is diesel-powered.

On average, U.S. freight railroads can move one ton of freight more than 470 miles per gallon of diesel fuel, thanks to the low-rolling resistance of steel wheels coupled with the energy efficiency of the diesel locomotive. According to the Association of American Railroads, the nation’s 64 freight railroads transit a network of nearly 137,000 freight rail miles.

In 2018, U.S. Class I railroads moved 1.5 million carloads of food products, 1.5 million carloads of grain and other farm products, 1.2 million carloads of lumber and paper products, 2.4 million carloads of chemicals, and 1.8 million carloads of motor vehicles and parts.

Where Fuel Measurements Meet Ultrasonic Sensors

Established in 2005, TMV Control Systems Inc. was formed from a vision to design and manufacture the next generation of locomotive control systems. Based on 22 years of experience designing locomotive control systems, Mr. Derick Vander Klippe’s pursuit was to offer the rail industry an advanced, robust control system with long-term performance.

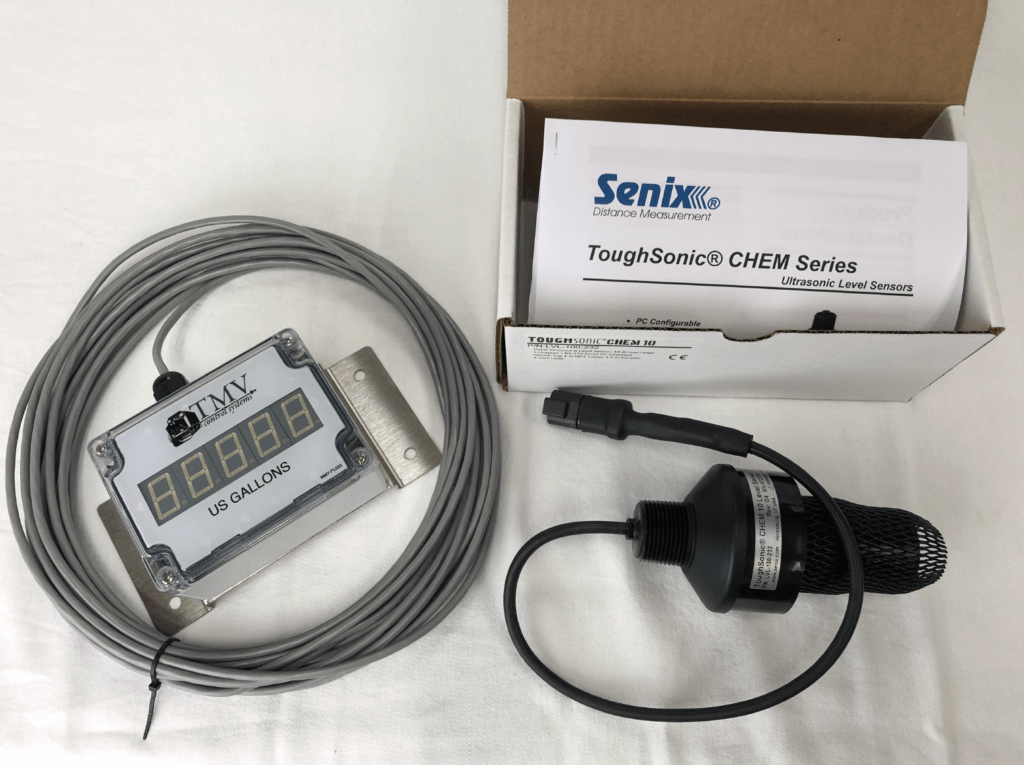

The result: the Traction Engine Control Unit (TECU), an intuitive system that is easy to navigate and operate to get the most out of an engine. Installed inside the high voltage Electrical Cabinet, the TECU I/O modules receive input from contactors, relays, current sensors, fuel level monitors, pressure sensors, oil sensors, and Senix ToughSonic-200 ultrasonic level sensors.

The TECU also receives control stand operations such as throttle direction, notch, brake, and many others. This data is viewable on a display screen located nearby, so users can see exactly what their vehicle is doing—from the inside out.

TMV used the now-discontinued ToughSonic-200.10 Level Sensor to detect fuel level in diesel-electric locomotive fuel tanks.

"We had the expertise to calculate fuel level based on the dimensions of the fuel tank, but we needed something that could accurately measure the level or height of fuel," said Vander Klippe.

Flow Rates vs. ToughSonics®

TMV Control explored options such as utilizing a flow rate to measure fuel level, but experienced difficulties with the serious conditions of the railroad: trouble under movement, vibration, alternating weather and temperature conditions, and inclines.

The Senix ultrasonic sensor can endure all those and still provide accurate readings. TMV Controls has selected the ToughSonic-200.10 due to its accuracy, ruggedness, and dependability. The TS-200.10 is made of PVDV, the transducer is protected by a layer of polyvinylidene fluoride (PVDF), the PUR jacketed cable and electronics are potted and protected, and all ToughSonic sensors have an IP68 rating.

Flow rates are notoriously inaccurate because fuel pumps out of the tank, but a return line pumps some back in. The incoming and outgoing fuels tend to be at different temperatures so that flow rate sensors can measure more fuel going back in the tank. Even small errors keep adding up.

Calculating the dimensions of the tank with the readings from the Senix ToughSonic-200.10 ultrasonic sensor is much more accurate. These sensors measure, record, and display fuel levels, and also measure kilowatt hours. Using these two measurements, railroads can determine the efficiency of locomotives and their engines.

For more information on how Senix can help with your application contact us at info@senix.com or click here.