CALL FOR PRICE

Tough environmental conditions are no match for the compact non-contact radar (CNCR). Small but mighty, CNCR-200 series sensors offer 1.5" NPT mounting and come in ranges of 26’ and 49’ to provide inventory control, automation abilities, and level measurements to a diverse scope of industries and applications.

Non-contact radar is the gold standard for small bins, tanks, and silos. Pair with ToughSonic® ultrasonic sensors for a comprehensive smart inventory management system.

Liquids or Solids: A leading choice for any industry that requires bulk material measurements

Small-Vessel Friendly: Perfect fit for tight spaces or hard-to-access hoppers, tanks, or bins

Real-Time Measurements: Integrate into BinCloud® software, walk-up displays, or PLCs

Variety of Mounting Options: Brackets and mounting plates to suit any bin, tank, or silo

The CNCR’s Advanced Features

The CNCR’s Advanced Features

80 GHz Technology: Narrow 8° beam is unaffected by dust, foam, or condensation

Incredible Accuracy: Precision within ±0.2 in. (5 mm) for CNCR-210 or ±0.08 in. (2 mm) for CNCR-220 and CNCR-230

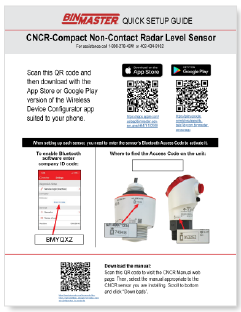

Bluetooth Configurable: Convenient sensor setup using Bluetooth on a cell phone

Durable Design: PVDF housings are heat, chemical, abrasion, weather, and flame resistant

NO Deadband/Dead Zone: Measure material up to the radar face without sacrificing accuracy

Big Radar Benefits

Non-Contact: CNCRs do not contact the material being measured, making them an ideal choice for sanitary or hygienic applications

Impenetrable & Protected: Enclosures are NEMA 4X and IP 66/67 rated against dust and water ingress

Installation Made Simple: Easily install through existing openings with a 1.5” threaded NPT or 1.5" threaded straight NPT connection

Safer Employees: Eliminate treacherous ladder climbing and liability, and lessen labor costs

Low Cost of Ownership: Radars require little to no maintenance after installation

View Inventory Remotely: With BinCloud® inventory management software, view data anytime, anywhere via phone, tablet, or PC

s

Common Applications for CNCR-200 Series Radars

Fat & Oil Processing: Obtain accurate inventory of hard-to-measure animal fats and viscous or clingy oils

Holding Tanks: Ensure continual water supply in water-cooled chillers and industrial water tanks

Bulk Solid & Liquid Plastics: Precise beam angle is well-suited for narrow plastic pellet silos, or for measuring liquid resins like epoxies, polyurethanes, and silicones

Municipal & Environmental Water Channels: Get visibility into sewer levels and view free-flowing water levels in rivers or dams

Fuel & Oil Tanks: Measure new and waste automotive fluids, or monitor diesel storage for uninterrupted operations

| Maximum Range | 49 ft. (15 m) for liquids; 25 ft. (7 m) for solids |

| Optimum Range | 0 inches to 32.81 ft. (10 m) |

| Deadband | N/A |

| Temperature | -40° to 140°F (-40° to 60°C) |

| Humidity | 0 to 100% operating |

| Protection | NEMA 4X, IP 66, IP 67 |

| Voltage | 12-35 VDC |

| Voltage Output | Loop-powered 4–20 mA |

| Accuracy | ±0.2 inches (5 mm) |

| Frequency | 80 GHz radar wave |

| Approvals | Ordinary locations |

Mechanical

| Housing | Polyvinylidene fluoride (PVDF) with FKM seal for heat and chemical resistance |

| Mounting |

1.5 inch threaded or straight NPT connection |

| Cable | Not included |

| Total Weight | 19.04 oz (0.54 kg) |

*Specifications are subject to change without notice.